Engineered coherence interferometry

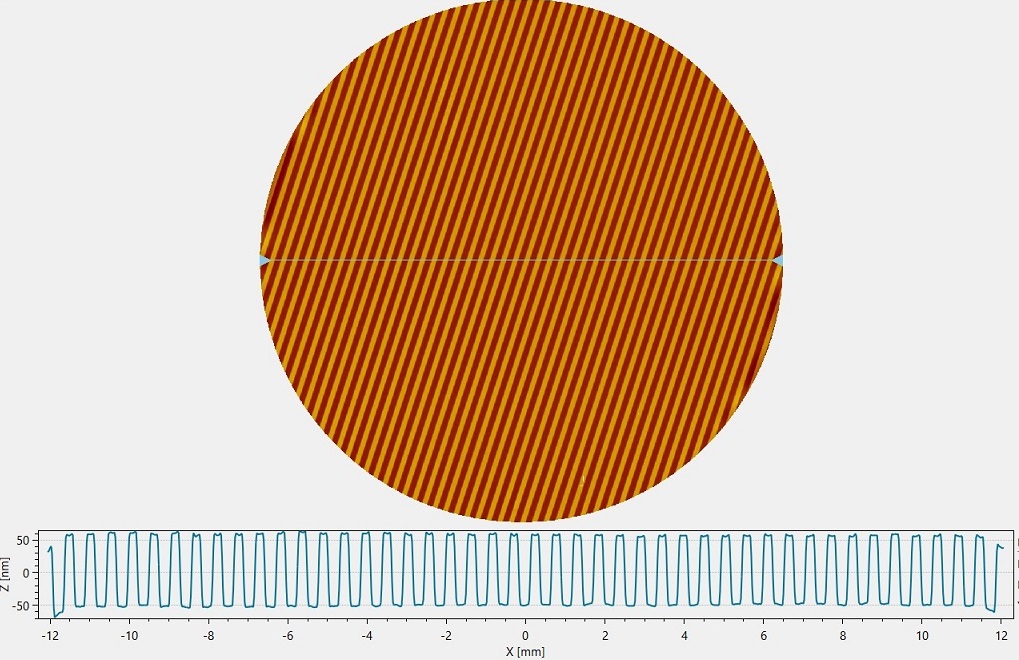

OptoFlat is designed specifically for testing plano-polished surfaces to sub-nanometer precision with minimal setup and user friendly software

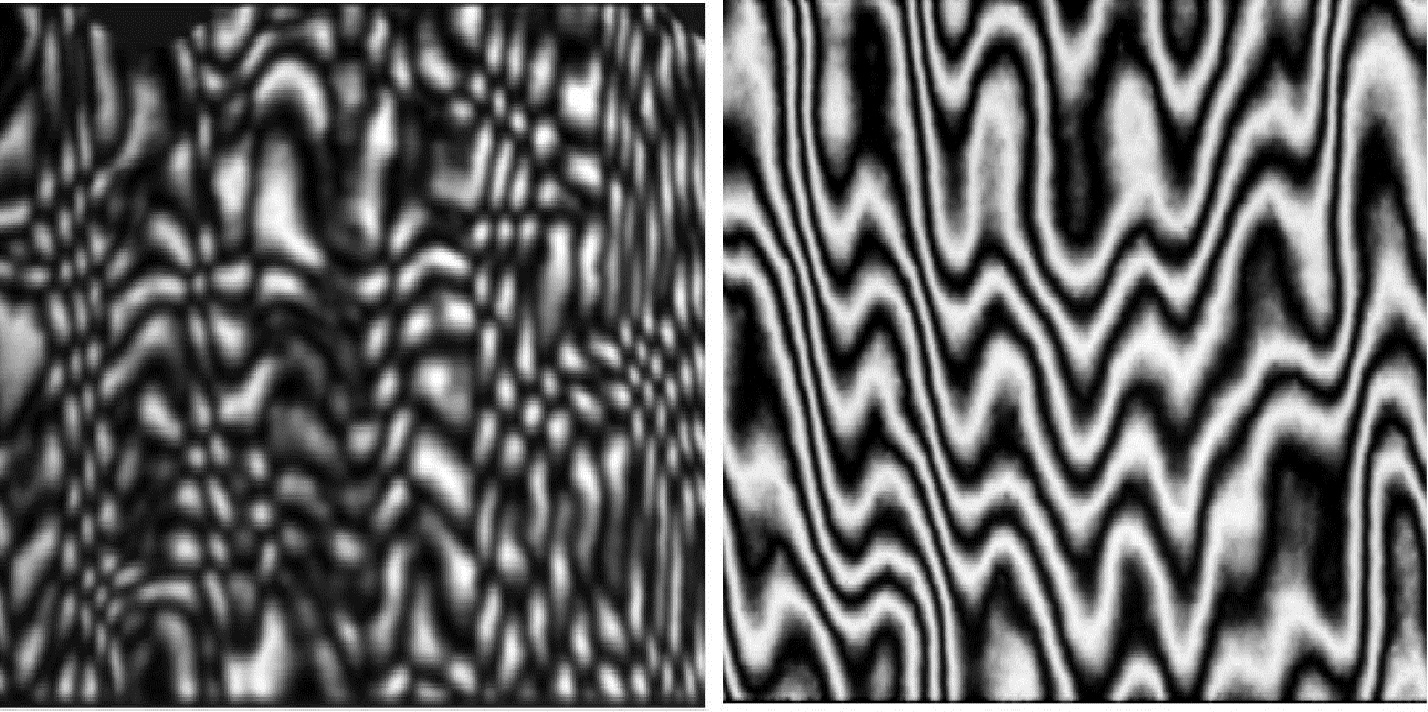

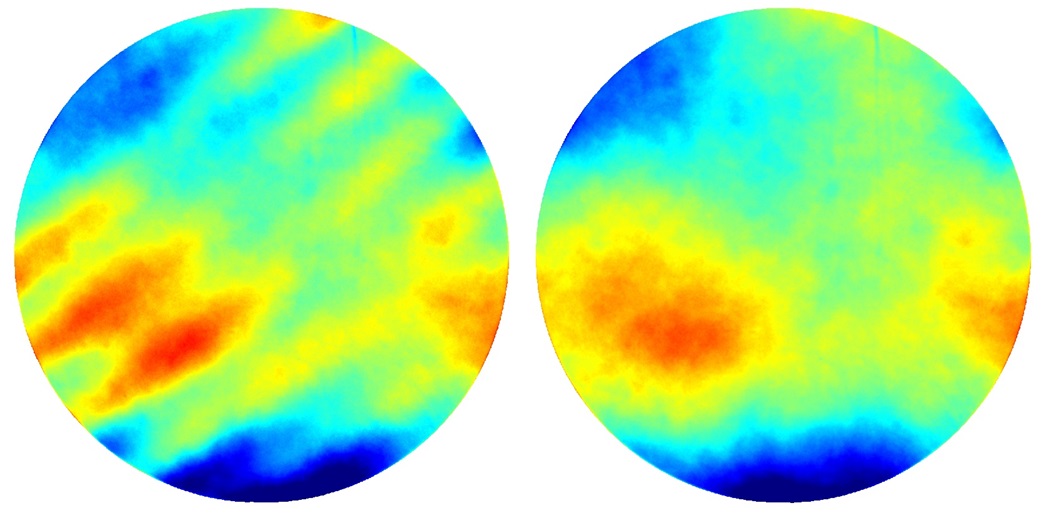

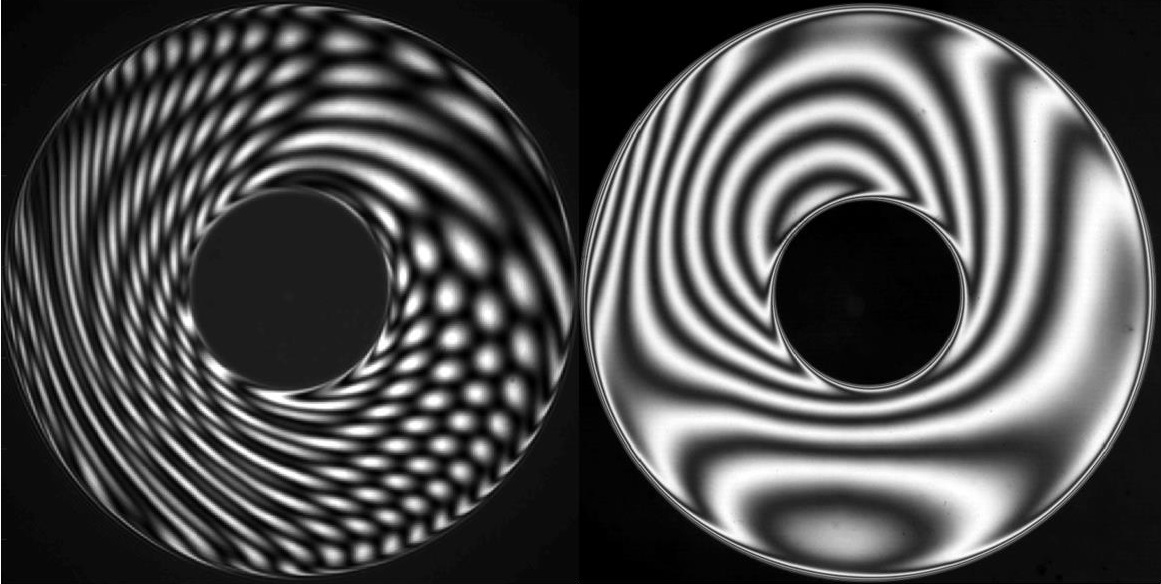

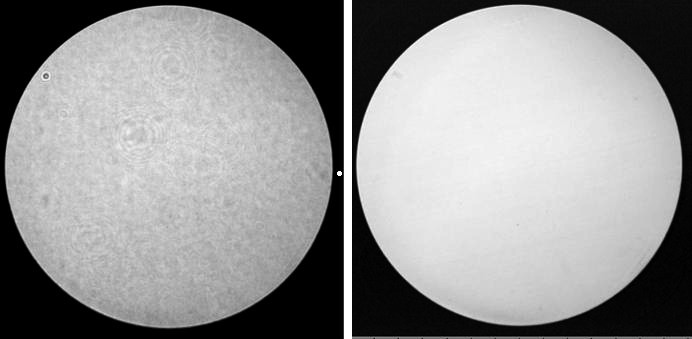

Spurious fringes of glass disk in laser Fizeau interferometer (left) compared to OptoFlat front surface (right)

Non-laser light source suppresses spurious fringes

With the advent of the laser as a coherent, narrow bandwidth wavelength light source, producing fringe patterns became relatively easy using laser interferometers in optical test setups. Due to the large temporal and spatial coherence of the laser source, interference can occur between any surface reflection and a reference beam, producing spurious fringes. Furthermore, scratches, dust particles and defects can cause diffraction ringing and other phase errors in the interference fringes due to the high spatial coherence of lasers.

Coherent artifacts in a laser Fizeau interferometer (left) compared to a low spatial coherent source (right)